metal hardness testing methods|types of hardness testing methods : online sales It’s important that engineers specify hardness testing methods correctly to ensure timely heat treatment and avoid costly delays. Common hardness testing methods are introduced below. Rockwell Hardness. This method tests the hardness of steel parts by applying loads to parts via either a tungsten carbide ball or a spheroconical diamond indenter.

Find out all of the information about the Biobase product: laboratory autoclave BKQ-H150 . Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale.

{plog:ftitle_list}

The primary difference between Class B and Class N autoclaves is how they remove air from the chamber prior to sterilization. Class B autoclaves utilize a vacuum pump to completely remove air from the .

types of hardness testing methods

laboratory autoclave ppt

Hardness testing works by pressing a standardized, hard instrument into the material that is being tested. The instrument, called an indenter, is pressed into the sample for a standardized length of time (a . Brinell hardness. The Brinell hardness scale is a widely accepted measure of hardness in materials. It involves pressing a ball of steel (or tungsten carbide for harder materials) into the test piece at a constant and known force. The softer the material, the deeper the ball will penetrate and vice versa. The next step is to take a measurement of the diameter of the . Metal testing is a collection of procedures and techniques to assess metal materials’ properties, integrity, and composition. These methods involves a range of assessments that include but are not limited to hardness, tensile .For the longest time I thought that the only way to properly check the hardness of metal was with a proper Rockwell testing machine. Thankfully, I’ve learned a few other methods and tricks over the years that have really made this more doable without needing a 00+ machine.

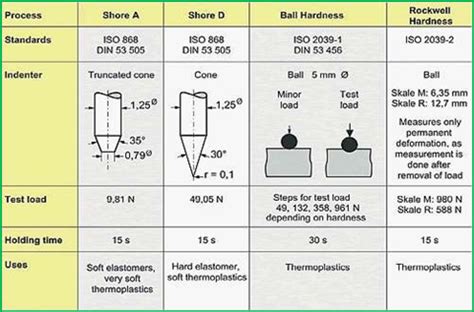

What Are the Different Types of Hardness Test Methods? Certainly! Hardness testing encompasses various methods to measure a material’s resistance to deformation when subjected to an applied force. Here are the different types of hardness test methods explained in more detail:e: . ISO 4545: This standard covers Knoop hardness testing for metals.

It’s important that engineers specify hardness testing methods correctly to ensure timely heat treatment and avoid costly delays. Common hardness testing methods are introduced below. Rockwell Hardness. This method tests the hardness of steel parts by applying loads to parts via either a tungsten carbide ball or a spheroconical diamond indenter.Here's a step-by-step instruction to guide you through a standard hardness testing procedure, in this case, we'll use the commonly used Rockwell hardness testing method as our guide: Selection of an appropriate scale: Different testing scales (e.g., Rockwell B or C, etc.) are designed for materials of varying hardness. Each hardness testing method has its characteristics and range of applications: The Brinell hardness test is suitable for various materials, especially annealed, normalized, quenched and tempered steel, cast iron, and non-ferrous metals. The Rockwell hardness test is suitable for a wide range of materials, using a smaller indenter for measurements. The Rockwell method offers a quick and accurate measure of hardness on almost all metals and some plastics (see Rockwell scales below). INNOVATEST FENIX 200 DCL . The Leeb hardness testing method, also known as the Equotip method, was first invented by a swiss company in 1975. This method measures the velocity of rebound when a carbide ball .

Rockwell hardness testing is somewhat comparable to Brinell hardness testing, in that it measures a metal’s resistance to penetration, however, it differs in that the depth of the impression is measured, rather than the diametric area in the case of Brinell.Due to its speed and simplicity, as well as the small size of the indentation and its ability to distinguish small .

ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview . The right hardness test method depends on the material being tested and the specific requirements of the application. . It is therefore, also the most commonly used method for metals testing on the U.S. market. The optical methods involve the use of a camera system, generally consisting of a digital camera, a light source, and lenses with . Material Hardness – Types, Testing Methods & Units. . Hardness testing must be carried out for each case so that a well-informed choice can be made for the application. . and a force is applied to the ball. This force will vary depending on the test metal being measured. The standard load is 3000 kg, but it may be reduced to 500 kg for .

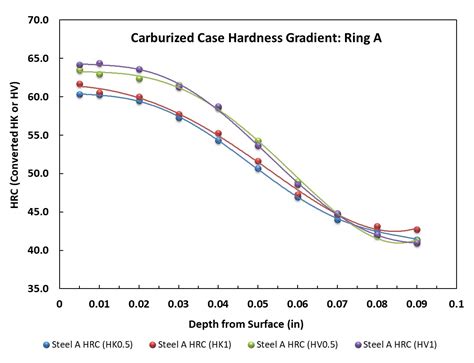

load hardness tests vs depth

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.Metal Hardness Testing: Common Methods 1. Rockwell Hardness Test: Principle: Measures the depth of penetration of an indenter under a large load compared to the penetration under a smaller load. Scales: Depending on the indenter and load used, different scales, such as Rockwell A, B, and C, are used. 1.5 Units— At the time the Rockwell hardness test was developed, the force levels were specified in units of kilograms-force (kgf) and the indenter ball diameters were specified in units of inches (in.). This standard specifies the units of force and length in the International System of Units (SI); that is, force in Newtons (N) and length in millimeters (mm). One vital feature it has is its ability to test a range of metals as well as alloys with less sample preparation making it useful in industry. . What types of hardness testing methods are there? A: Rockwell (ASTM E18), Brinell .

Using test methods such as scanning electron microscopy, hole-drilling strain-gage method, semiautomatic and automatic image analysis, and X-ray diffraction, parameters like elastic moduli, impact strength, ductility, hardness, residual stress, and grain size are measured.

This method is suitable for materials with coarse surfaces or irregular shapes and is widely used in the testing of metals. . What are the main types of hardness testing methods, and how do they differ? The primary types of hardness testing methods include Rockwell, Brinell, and Vickers hardness testing. .Hardness testing is a common method of testing metals. It is quite easily and economically performed, and there is a clear affiliation between hardness and some other mechanical properties of steel. High hardness usually means high tensile strength with possibly lower ductility and conversely low hardness equates to low strength.

The Leeb hardness test is a non-destructive and portable method used primarily for metals. It involves a spring-loaded end with a spherical or conical indenter. The end that makes contact with the material is released, and the rebound velocity is measured after striking the material's surface.The specific size, shape, and location requirements of the hardness test determine the use of the Vickers method. One of the key advantages of the Vickers Hardness test is its versatility, as it can be applied to a wide range of materials and properties. Vickers Macro Hardness testing standards we work with: BS EN ISO 6507-1:2018 (HV1, HV5, HV10)Macro hardness testing A ground surface is usually sufficient, and sometimes no preparation is required. Micro hardness testing Due to the lower loads used during hardness testing, micro hardness testing requires a polished or electropolished surface. It is important that the borders/corners of an optically evaluated impression are clearly visible. Essentially, hardness is only a measure of how well a material performs in a given hardness test. As a result, there are various hardness testing methods and techniques available to researchers today. In this article, we want to look into the four different methods of indentation hardness testing methods. Rockwell Hardness Testing

The Leeb Rebound Hardness Test (LRHT), invented by Swiss firm Proceq SA, is one of the four most commonly used methods for metal hardness testing. This portable method is mainly used to test large enough workpieces (basically more than 1kg). It is a kind of non-destructive test used to test the large workpieces weighing more than 1kg. This article provides an overview of common hardness testing methods for metals, comparing their applications, benefits, and drawbacks, and includes a comprehensive table to guide method selection. Additionally, it addresses industry standards and troubleshooting techniques to maintain accuracy and repeatability in testing. This guide is .

To determine dynamic hardness, the indenter is forced under high loading rate which leads to impact or chock the test material. Thus, the indenter could be shot the tested material like a projectile onto the target surface (Low 2006; El-Ezz 2007).The test material must be permanently deformed, so the kinetic energy should be chosen to assure plastic .A Guide to Selecting the Right Hardness Testing Method. Battery Cell Technology: Key Mechanical Testing Methods for Advanced Cell Production; Boosting Throughput and Reducing Labor Costs with Automated Testing in Plastics Manufacturing; How Automated Testing Systems Boost Throughput While Addressing Unique Metal Challenges; MD&M West 2023: See .

China Vertical Autoclave wholesale - Select 2024 high quality Vertical Autoclave .

metal hardness testing methods|types of hardness testing methods